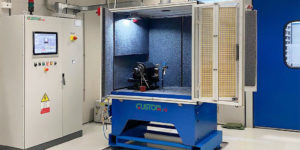

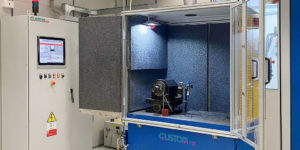

These HW / SW systems are designed to test the performance of bearings.

The supply of these systems includes the realization of a turnkey system including “ad hoc” software for the supervision of the testing process; engineering and construction of the mechanical, electrical, pneumatic and hydraulic equipment for automation.

The working principle of the system is to measure the standard bearings’ characteristics as the friction torque, axial and radial forces, and temperatures depending on the speed. The system can be described by the following steps:

- PC: the supervision software is developed in LabVIEW and contains the operator interface and the historical database. This component is used to manage the test parameters, to track the historical data and alarms and save the test report.

- CompactDAQ: implements the scheduling of the test steps and regulation of the loads applied to the bearings.

- Electric cabinet: contains the servo-drive to manage the motor power for the bearing’s motion and to condition the signals supplied by the sensors.

Main Products:

- Software Universal TB

- Universal Bearings Testing Benches